Footing Dimension Calculator

Verify Your Footing Dimensions

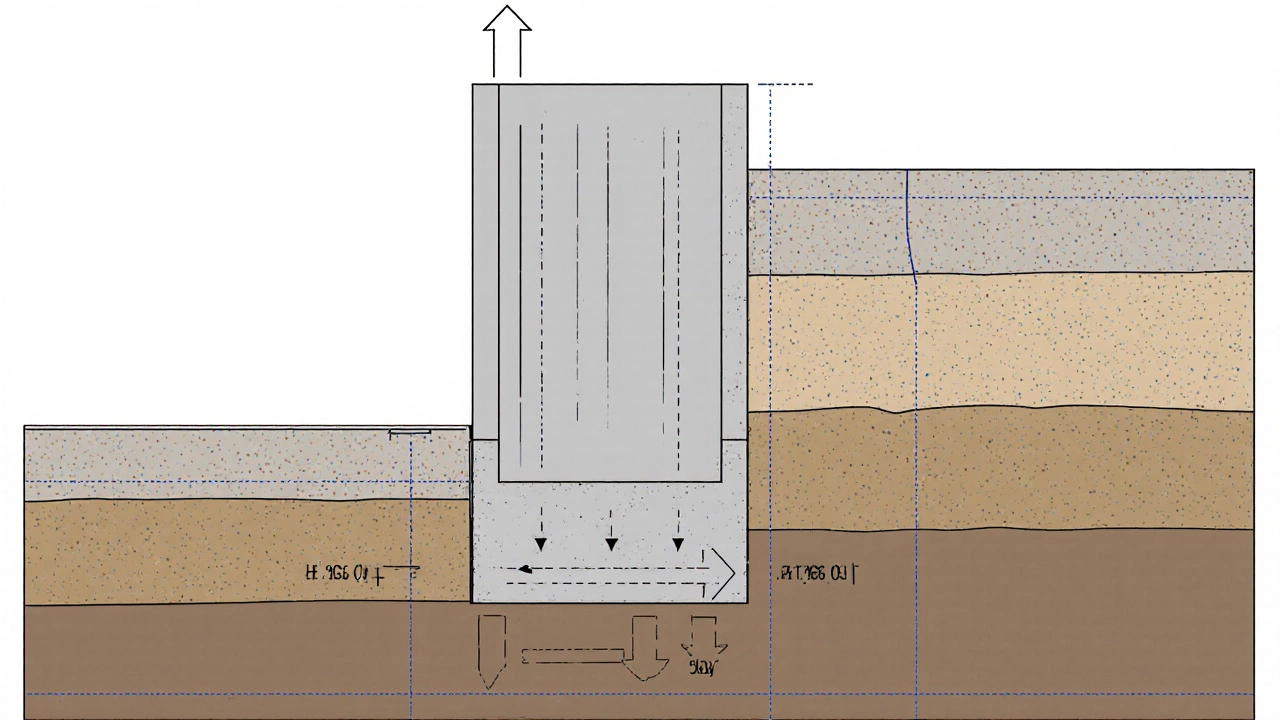

Calculate if your foundation meets the critical 1:3 rule. For every 1 meter of wall height, the footing must extend at least 3 meters horizontally.

The 1:3 rule in construction isn’t a magic number-it’s a simple, proven guideline that keeps buildings standing when they’re under pressure. You’ll hear it mentioned on job sites, in engineering meetings, and in building code handbooks. It’s not flashy, but if you ignore it, you risk cracked walls, sagging floors, or worse. This rule applies most often to concrete footings and load-bearing walls, and it’s one of those things that separates professional builds from DIY disasters.

What Exactly Is the 1:3 Rule?

The 1:3 rule states that for every 1 unit of vertical height a load-bearing wall or column carries, the footing or base supporting it must extend at least 3 units horizontally. Think of it like a pyramid: the wider the base, the more stable the structure above it. If a wall is 1 meter tall, its concrete footing should be at least 3 meters wide. That’s not just extra concrete-it’s insurance against uneven settling, soil movement, or heavy loads from upper floors.

This isn’t arbitrary. It comes from basic physics. When a wall pushes down on the ground, the force spreads out. If the footing is too narrow, the pressure on the soil becomes too high. Soil can’t handle infinite pressure. Clay soils might heave. Sandy soils might shift. Even solid bedrock can crack under concentrated stress. The 1:3 ratio gives the load enough room to disperse safely into the earth.

Where Is the 1:3 Rule Applied?

You’ll see this rule in action in three main places:

- Concrete footings under load-bearing walls-especially in commercial buildings with multiple floors or heavy equipment. A warehouse with heavy machinery on the second floor? The walls supporting that weight need wide, deep footings.

- Retaining walls-these hold back soil and need massive bases to resist lateral pressure. A 1-meter-high retaining wall should have a footing at least 3 meters wide to prevent tipping or sliding.

- Column bases-in steel-framed buildings, the base plates under steel columns often follow this ratio when embedded in concrete piers.

It’s not used for non-load-bearing partitions, interior drywall, or light roof trusses. Those don’t carry enough weight to need such a wide base. But for anything that holds up a roof, floors, or heavy equipment? The 1:3 rule is non-negotiable.

Why Not Just Make the Footing Bigger?

You might think, “Why not make the footing 5 meters wide instead of 3? More is better, right?” Not always. Oversizing footings wastes money, increases excavation time, and can even cause problems. Too much concrete can trap moisture, leading to cracking. It also adds unnecessary weight, which might overload the soil below instead of helping it.

The 1:3 ratio isn’t about being generous-it’s about being precise. Engineers calculate soil bearing capacity, live loads, dead loads, and seismic factors. They use those numbers to find the minimum footing width that meets safety standards. In many cases, 1:3 is the sweet spot between safety and cost. Going wider might give you a safety margin, but it’s not always needed.

Take a real example: a two-story retail building in Wellington. The ground floor walls carry the weight of the second floor, roof, and stored inventory. Engineers calculated the total load at 12 tonnes per linear meter. The soil here is silty clay with a bearing capacity of 150 kPa. Using standard formulas, the required footing width came out to 2.9 meters-close enough to 3 meters to follow the 1:3 rule. They didn’t go to 4 meters. They didn’t cut it to 2.5. They used the rule as a starting point and refined it with math.

What Happens When You Break the Rule?

Ignoring the 1:3 rule doesn’t cause instant collapse. It causes slow, silent failure. You might not notice anything for months-or even years.

- Cracks appear in the walls, starting at the corners and running upward.

- Doors stick because the frame is no longer level.

- Floors slope slightly, especially near the center of the building.

- Water pools near the foundation because the ground has settled unevenly.

These aren’t just cosmetic issues. They’re signs of structural stress. In commercial buildings, this can mean costly repairs, tenant complaints, or even building code violations. In 2023, a Wellington retail center had to shut down for six weeks after inspectors found footings under its main load walls were only 1.8 meters wide for 1.2-meter-high walls-a 1:1.5 ratio. The fix? Excavate, pour new 3.6-meter-wide footings, and reinforce the walls. Cost: $280,000. A $40,000 mistake that could’ve been avoided with a simple ratio.

Is the 1:3 Rule Always Right?

No. It’s a rule of thumb, not a law. In some cases, you’ll need more than 3 units of width. In others, you can get away with less.

For example:

- Hard rock foundations can support narrower footings because the load doesn’t spread as much-it’s transferred directly through the rock.

- Soils with high bearing capacity (like dense gravel) may allow 1:2 ratios.

- Seismic zones (like Wellington) often require wider footings than 1:3 to handle lateral forces during earthquakes.

- Lightweight structures like metal sheds or storage units may only need 1:1.5 if the load is minimal.

The key is this: the 1:3 rule is your starting point. A baseline. Always consult a structural engineer when designing commercial buildings. They’ll run soil tests, calculate actual loads, and tell you if 1:3 is enough-or if you need 1:4 or even 1:2.

How to Check If Your Project Follows the 1:3 Rule

If you’re managing a commercial build, here’s how to verify:

- Measure the height of the load-bearing wall from the bottom of the footing to the top of the wall.

- Measure the width of the concrete footing at its base.

- Divide the footing width by the wall height. If the result is 3 or higher, you’re good.

- If it’s less than 3, ask your engineer why. Don’t assume it’s fine just because the building hasn’t collapsed yet.

Keep a copy of the structural drawings on site. The footing dimensions should be clearly marked. If they’re not, push back. It’s your responsibility to make sure the build is safe.

What About Modern Materials?

You might think that with steel frames, reinforced concrete, and advanced soil stabilization, the 1:3 rule is outdated. But it’s not. Even with modern tech, the physics hasn’t changed. Steel beams still need solid bases. Concrete slabs still transfer load to the ground. The 1:3 rule is a simplified version of complex engineering calculations-but it’s still accurate enough for most commercial applications.

What has changed is how we use it. Today, engineers use software to model soil behavior, simulate earthquake forces, and optimize footing shapes. But even the most advanced programs start with the same principle: wider bases handle more load. The 1:3 rule is the foundation of those models.

Final Thought: It’s Not Just About Concrete

The 1:3 rule isn’t just about width. It’s about thinking ahead. It’s about understanding that every structure is a chain of forces-each part holding up the next. A wall holds up a floor. A footing holds up the wall. The ground holds up the footing. If any link is weak, the whole system fails.

In commercial construction, shortcuts cost more in the long run. The 1:3 rule is one of the oldest, simplest, and most reliable ways to avoid those costs. It doesn’t require fancy tools. Just a tape measure, a calculator, and the discipline to follow it.

Is the 1:3 rule the same for residential and commercial buildings?

The principle is the same, but the application differs. Residential homes often use lighter materials and smaller loads, so footings may follow a 1:2 or even 1:1.5 ratio. Commercial buildings carry heavier loads-equipment, multiple floors, large crowds-so the 1:3 rule is more commonly required. Always check local building codes; some cities require 1:3 for all new construction, regardless of type.

Can I use the 1:3 rule for a retaining wall?

Yes, and it’s especially important here. Retaining walls face sideways pressure from soil, not just downward weight. A 1:3 footing width helps resist tipping and sliding. For walls over 1.5 meters tall, you’ll often need additional reinforcement like geogrids or tiebacks. The 1:3 rule is the minimum starting point.

Does the 1:3 rule apply to pile foundations?

Not directly. Pile foundations transfer load deep into the ground through shaft friction or end-bearing, so they don’t rely on wide footings. But the cap beam that connects multiple piles often follows the 1:3 rule to distribute the load evenly across the pile group. The rule shifts from footing width to cap dimensions.

What if my soil is unstable?

If soil tests show low bearing capacity-like in peat, soft clay, or reclaimed land-you’ll need more than just a wider footing. Options include deeper footings, soil compaction, grouting, or using piles. The 1:3 rule alone won’t fix bad soil. Always run a geotechnical report before pouring concrete.

Can I skip the 1:3 rule if I’m using reinforced concrete?

No. Reinforcement helps concrete resist cracking under tension, but it doesn’t change how load spreads into the soil. A reinforced footing that’s too narrow will still over-pressurize the ground, leading to settlement. The 1:3 rule is about geometry and soil mechanics, not material strength.

Author

Damon Blackwood

I'm a seasoned consultant in the services industry, focusing primarily on project management and operational efficiency. I have a passion for writing about construction trends, exploring innovative techniques, and the impact of technology on traditional building practices. My work involves collaborating with construction firms to optimize their operations, ensuring they meet the industry's evolving demands. Through my writing, I aim to educate and inspire professionals in the construction field, sharing valuable insights and practical advice to enhance their projects.